News Releases

September 25, 2023

Energy-saving effort for a future decarbonized society

Electricity consumption reduction in the ripening process by approximately 25%

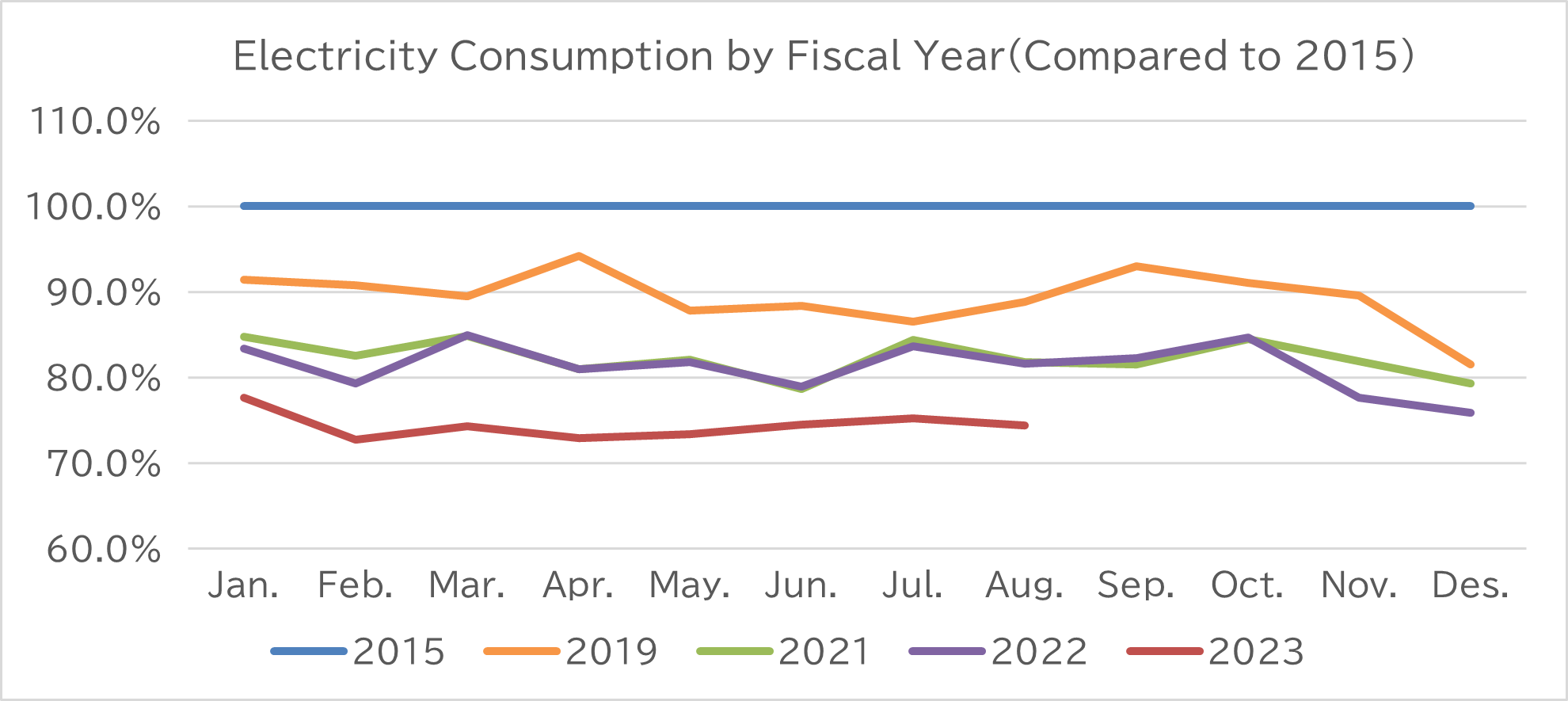

Farmind Corporation (Headquarter: Chiyoda-ku, Tokyo; President and CEO: Tatsuo Horiuchi; hereafter "Farmind"), establishing a nationwide comprehensive fruits and vegetables cold chain network has been working to conserve energy and reduce greenhouse gases for a decarbonized society. First solar power generation was installed in Hiroshima center in April 2011.In addition, from September 2017, each center has sequentially installed the LED fluorescent lamps inside, and installations are expected to be completed to all centers by the end of the year. In order to respond to issues such as rapid changes in the social environment in recent years and tight demand for electricity, since 2019 Farmind has been working to reduce the electricity consumption in the ripening process, one of our core business. In 2022, Farmind succeeded in reducing the electricity consumption in ripening process by approximately 20% compared to 2015, and as of July 2023, reducing by approximately 25%.

| 【Trends in Electricity Consumption by Fiscal Year】*Ratio of electricity consumption is compared to the same month in 2015 |

|

Farmind ripens fruits and vegetables such as bananas, avocados, and kiwifruits. Approximately 30% of bananas, the No.1 fruit consumed*1 in Japan, are ripened*2 in Farmind centers nationwide. All ripening processes are centrally controlled by computer and skilled technicians perform detailed inspections. Through those process, Farmind will be able to supply fruits and vegetables of stable quality and ripeness. Approximately 100 patterns are set for each center according to the environment, such as items, climate, and equipment. The temperature and humidity in the ripening rooms are constantly controlled 24 hours a day. There are 3 main types of power used to manage the temperature and humidity: refrigerators, heaters, and differential pressure fans. With the goal of reducing the electricity consumption in ripening process by 30%, Farmind has improved the processing pattern and makes it possible to save electricity while maintaining quality. Farmind will continue to save electricity and contribute to the realization of a decarbonized society.

Based on its corporate philosophy of "linking producers and consumers," Farmind will continue to make environmentally friendly efforts to realize a sustainable society, while contributing to quality improvement and the development of fruit and vegetable distribution in Japan and overseas by utilizing its cold chain network.

|

|

| Farmind dedicated Fruits and Vegetable Center (Kobe Center) | 24-hour strictly control by computer |

|

|

| Regular checks by skilled technicians | Ripening rooms in Farmind Kobe center |